How Do You Repair An Abs Joint Leak

- #two

A picture of the piping would exist helpful. Depending on what is in that location, I would probably be cutting a section out and replacing information technology. The new section tin can exist spliced in using ABS couplers, banded couplers, or both.

![]()

jadnashua

Retired Defense Industry Engineer xxx

- #3

Cutting information technology out and replacing from a convenient point, rejoining the bits with either repair couplings ( a coupling without a eye terminate that gets glued in place to rejoin the pipe) or banded couplings works well. But, depending on what you are going to be fixing, they do make special drill bits that can ream the pipe out of an existing coupling - RamBit is one brand. For a one-time use, you may just want to cut things out and replace, though.

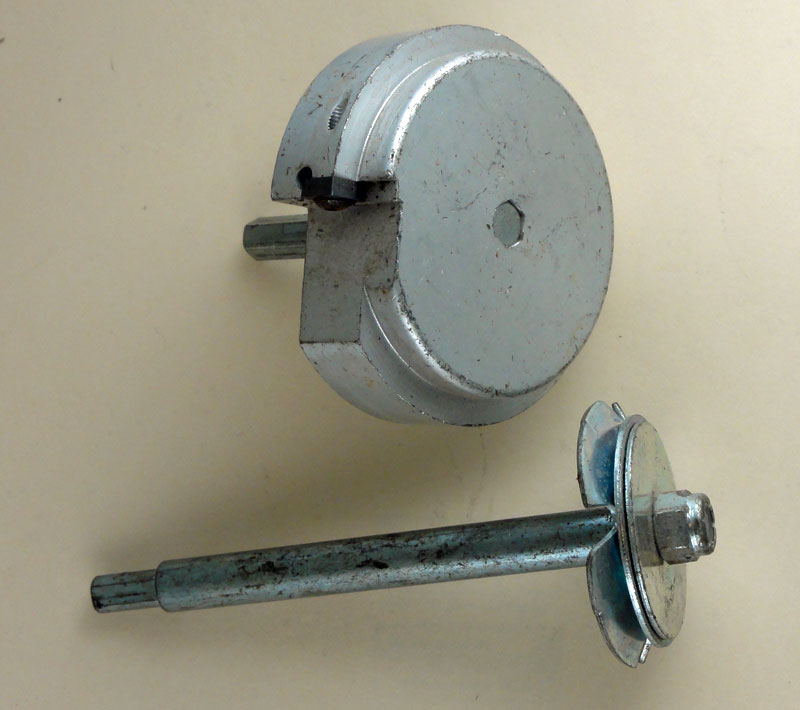

Reed Pipe Reamer, and a Ram-Chip

Last edited past a moderator:

![]()

jadnashua

Retired Defence Industry Engineer xxx

- #5

There is an art to using repair couplings, since when both ends are fixed, y'all take to slide it all the way on one pipe at each cease, then put it in identify, then slide it back, getting information technology centered on the joint on each end before the cement sets enough to make it incommunicable to motility information technology!

Get some banded couplings (y'all'll demand two), cut that section out with the joint on it so that you have a slice long enough to fully appoint both of the new couplings you demand to install. FIrst, loosen the clamps plenty and so y'all can slide the banded reinforcement sleeve off, slide that on the pipe. THen, put half of the rubber sleeve on the pipe, then fold the other half back onto itself. Do that for both ends. WHen you and then put the replacement section in at that place to put things back together, you fold the condom sleeve onto the other pipe, slide the metal reinforcement sleeve back centered over it, so tighten upwardly the clamps. The banded reinforcement holds the two pipe ends aligned, and at that place's a rubber ridge in the sleeve that centers it and provides a stop and then you know you've got information technology fully on. You only need plenty slop in the cutting to account for the thickness of the rubber end at each terminate...IOW, the new slice of pipe should exist just a trivial shorter than the opening. It works best if y'all get your cuts nice and square, otherwise, you need a bit more slop to get it all to fit together. A pro might so apply a torque screwdriver or nut driver to tighten the things up. Dont' remember the recommended torque, but I retrieve it'due south around 15#...you should cheque this if you employ those connectors.

- #9

Ok. I think I've seen the type of coupling you guys are talking about. Is that kind of coupling Ok as a permanent repair? I thought you lot but used those types of couplings for joining two pipes of dis-like material together?

You volition find the fittings shown in a higher place harder to piece of work with than a non shield fitting. The ones above have a affront in the middle designed to go along cast iron pipe from touching each other.

A non shield no-hub is wider and slides back and along easier. Canonical for permeant apply as long equally it is not a multi family housing dwelling or commercial space. Then the shield and cast iron pipage is required.

JW

How Do You Repair An Abs Joint Leak,

Source: https://terrylove.com/forums/index.php?threads/repairing-a-leaky-joint-in-abs.55730/

Posted by: spearsstintion.blogspot.com

0 Response to "How Do You Repair An Abs Joint Leak"

Post a Comment